How are welded beams made

Gulf States Saw & Machinery Co. Beam Layout Welders Manufacturers and Suppliers produce different sizes. It all depends on the needs of each client. The best thing is to invest in an I beam supplier and manufacturer. You can not only get the best prices but also get assistance when it comes time to install.

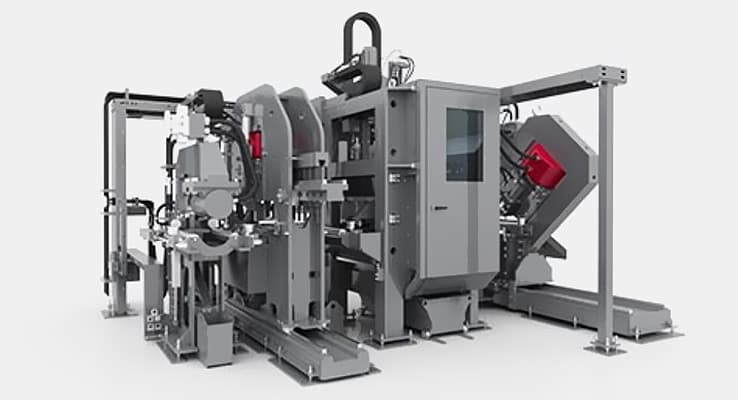

.jpg)